Solution 1: Pharma and Food industry transportation management

————Temperature, Humidity, Real-time monitoring

1. Wireless Magnetic 30 days long standby,12000/24000 MAH

2. Accuracy temperature: ±0.5℃ Humidity: ± 3%RH (25° C)

3. Vibration anti-theft alarm

4 Support 2G/4G for the global market

5. FDA, CRF 21,ANVISA certification

Solution 2: Correct & Safe Solution for Transporting COVID Vaccines

in all temperature ranges————Pfizer,Moderna,Sinopharm etc

TransportPfizer vaccine monitoring dedicated

The whole process involving Pfizer's vaccines is very strict because according to the manufacturer's specifications and ANVISA standards, the vaccine must be carried between -90°C and -60°C. Using a dedicated PT1000 sensor ⚠️ , sensor support temperature -100°C and +100°C

Therefore, vaccines are distributed across the country under the control and responsibility of our client's company's special thermal packaging, guaranteeing a super-negative range in a more uniform manner, fully maintaining the integrity of the vaccine and ensuring correct immunization.

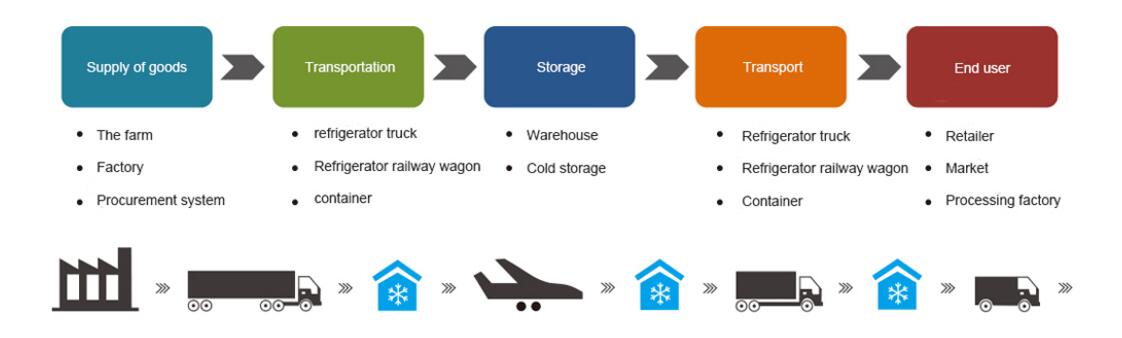

During cold chain logistics (refrigerated truck GPS), we often encounter:

The vehicle enters the warehouse to cool down in advance, and the temperature can only be entered into the warehouse for loading. This is known in the industry, but it is difficult to implement.

When the vehicle is driving, some drivers often turn off the cooler to stop the cold in order to save fuel.

If the temperature is abnormal during the process, the company needs to know and remedy the first time.

When the business season is high, outsourced vehicle management is really a headache.

The temperature is not as low as possible, the company only needs to ensure that the goods are always at a safe temperature range.

For the assessment of timeliness, companies want to achieve automation and standardization, and reduce human intervention!

Handling goods is the most prone to problems. Opening the door for a long time can easily cause the temperature of the goods to rise!

The above problems are happening every day in the industry, and many companies have adopted various governance methods, but from the results, they are not ideal. The reason is that they have not grasped the root cause of the above problems. Information asymmetry. Because of the asymmetry, the above problems frequently occur in the cold chain logistics process. The only solution to this problem is to achieve full-process information transparency. Mainly, it is to realize the transparent information of vehicles entering the warehouse, transporting in transit, and transferring to the station.

The warehouse enters the cold storage. Before the vehicle enters the cold storage for loading, it continuously collects the temperature change of the compartment. After the temperature drops to the loading requirements, it can be allowed to enter the cold storage for loading.

For the transportation process, it is necessary to achieve transparent monitoring of the entire temperature to ensure that the temperature data is fully visualized.

On the one hand, the temperature in the cargo hold is collected in real-time by a temperature detection device, and an open and transparent display is realized. On the other hand, the biggest factor that affects the temperature during the whole process-the cold machine, to ensure that the whole process is cold.

During the delivery process, it is necessary to ensure continuous cold, strictly restrict the door opening time, and reduce temperature rise damage.

Establish a complete cold chain monitoring platform to limit the time and number of door openings to reduce the impact of cargo quality on temperature. Real-time monitoring and feedback of temperature information through the temperature sensing device. In addition, the transfer process is pushed in real-time to realize electronic receipts.